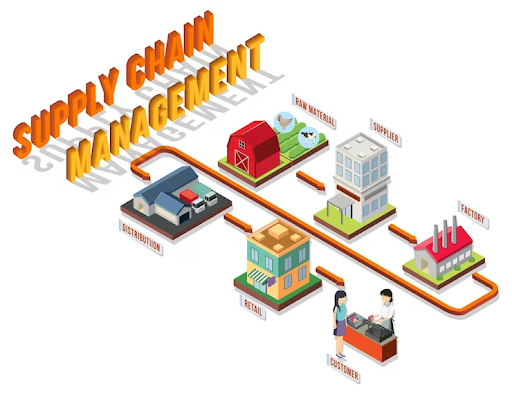

Supply chains are the backbone of global businesses, ensuring that products and services reach customers efficiently. However, in today’s interconnected world, supply chain disruptions have become an unfortunate reality. From natural disasters to geopolitical tensions and now even a global pandemic, these disruptions can have far-reaching impacts on businesses worldwide. In this post, we will explore the causes of supply chain disruptions and delve into their profound effects on global companies. We will also discuss strategies for managing these challenges, and share a compelling case study highlighting the devastating impact of the 2011 Japan earthquake and tsunami. Besides, if you’re looking for help with setting up your business, Formationwise corporate services is the right choice for you.

Definition of a Supply Chain Disruption

Supply chain disruptions can have a major impact on the flow of goods and services, not to mention business operations. Possible causes include natural disasters, labor strikes, economic downturns, and unexpected events. The consequences can involve delays or even the cessation of supplies, resulting in increased costs and decreased customer satisfaction. Companies should plan ahead for these disruptions by establishing strategies and protocols so they are prepared for whatever comes their way. That way, they can reduce the negative repercussions that supply chain disruptions may bring.

Causes of Supply Chain Disruptions

Supply chain disruptions can have various origins, each carrying its own set of difficulties. Natural disasters like earthquakes, hurricanes, or floods can damage transportation infrastructure and disrupt the flow of goods. Political instability or conflicts could lead to trade restrictions, border closures, or civil unrest impacting the transport of goods between countries. Technological failures and cyber-attacks may bring operations to a halt due to system glitches or data breaches, resulting in delays and information loss. The recent COVID-19 pandemic caused lockdowns and travel restrictions interfering with production processes and creating shortages of products. Supplier issues such as bankruptcy or financial troubles are other risks that can cause ripple effects through a network. Labor disputes and strikes may momentarily stop operations until a settlement is accomplished. Establishing strategies to recognize these potential causes of disruption and reduce their impacts is a must for businesses.

The Impact of Supply Chain Disruptions

Supply chain disruptions can have a significant impact on global businesses, causing ripple effects across industries and economies. These disruptions refer to any unexpected event or circumstance that interrupts the smooth flow of goods, services, or information within a supply chain network.

One major consequence of supply chain disruptions is increased costs. When key suppliers are unable to deliver materials or components on time, companies may be forced to source from alternative suppliers at higher prices. This can eat into profit margins and ultimately lead to price increases for consumers.

Another impact is delayed delivery times. If there are disruptions in transportation networks or customs processes, products may not reach their intended destinations as scheduled. This can result in customer dissatisfaction and potential loss of business.

Furthermore, supply chain disruptions can also lead to inventory shortages. Just-in-time inventory management practices rely on precise timing and coordination between suppliers and manufacturers. Any disruption in this process can cause shortages and production delays.

Moreover, supply chain disruptions have the potential to damage brand reputation. If customers experience consistent delays or product quality issues due to supply chain problems, they may lose trust in the company’s ability to deliver reliable products.

Global businesses must also consider the long-term consequences of supply chain disruptions on their overall resilience strategies. It becomes crucial for organizations to evaluate their vulnerabilities and implement measures such as diversifying suppliers or investing in technology solutions that enhance visibility across the entire supply chain network.

In conclusion (as per instructions), it is evident that supply chain disruptions can have far-reaching impacts on global businesses – affecting costs, delivery times, inventory levels, brand reputation, and overall business resilience strategies.

Managing Supply Chain Disruptions

When it comes to managing supply chain disruptions, businesses should be mindful of the need for preparedness. While it is impossible to completely eliminate this risk, diversifying your supply chain and sourcing locations, building resilience into operations, leveraging technology and conducting regular risk assessments can help mitigate their impact. Additionally, maintaining strong relationships with suppliers and reviewing contracts ensures that any issues can be identified quickly and are dealt with efficiently. Taking these measures can reduce the impact of disruptions on a business’s operations while allowing them to remain functional during uncertain times.

Case Study: The 2011 Japan Earthquake and Tsunami

The 2011 Japan Earthquake and Tsunami was one of the most destructive natural disasters in recent memory, bringing far-reaching repercussions for numerous industries around the globe. In particular, it posed significant challenges to global businesses in automotive and electronics, with many manufacturing plants suffering extensive damage or being forced offline due to power outages. Companies such as Toyota, Honda, Sony and Panasonic experienced drastic disruptions in their supply chains. This included a lack of vital components sourced from Japan, causing delayed production schedules and reduced product availability worldwide. In reaction to this crisis, companies initiated business resilience strategies such as supply chain diversification or contingency plans designed to mitigate any risks born from over-reliance on single sources.

Conclusion

To sum up, it is essential for organizations to take the necessary steps towards enhancing their supply chain resilience in order to effectively mitigate potential disruptions caused by external factors. Short-term investments in crisis preparedness will go a long way in ensuring ongoing operational continuity and business success well into the future.